Filling Machines Market Outlook

The global filling machines market was valued at nearly USD 8.10 billion in 2024. The industry is further projected to expand at a CAGR of 5% during the forecast period of 2025-2034. This growth is driven by a range of factors, including the increasing demand for automation in the packaging industry, advancements in technology, and the expansion of various end-use sectors such as food and beverages, pharmaceuticals, chemicals, and cosmetics. The rising focus on improving efficiency, reducing waste, and ensuring product safety is further fueling the adoption of filling machines across industries.

As industries strive to meet higher production standards and regulatory requirements, filling machines have become integral to streamlining operations and ensuring precision in filling processes. The growing emphasis on reducing labor costs and enhancing production efficiency is also contributing to the rising adoption of filling machines globally.

Filling Machines Market Share

This rise in market size can be attributed to the ongoing shift toward automation in industries such as food and beverage, pharmaceuticals, and personal care products. Filling machines are essential for industries requiring precise filling of products into containers, ensuring accuracy and consistency in production lines.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/filling-machines-market/requestsample

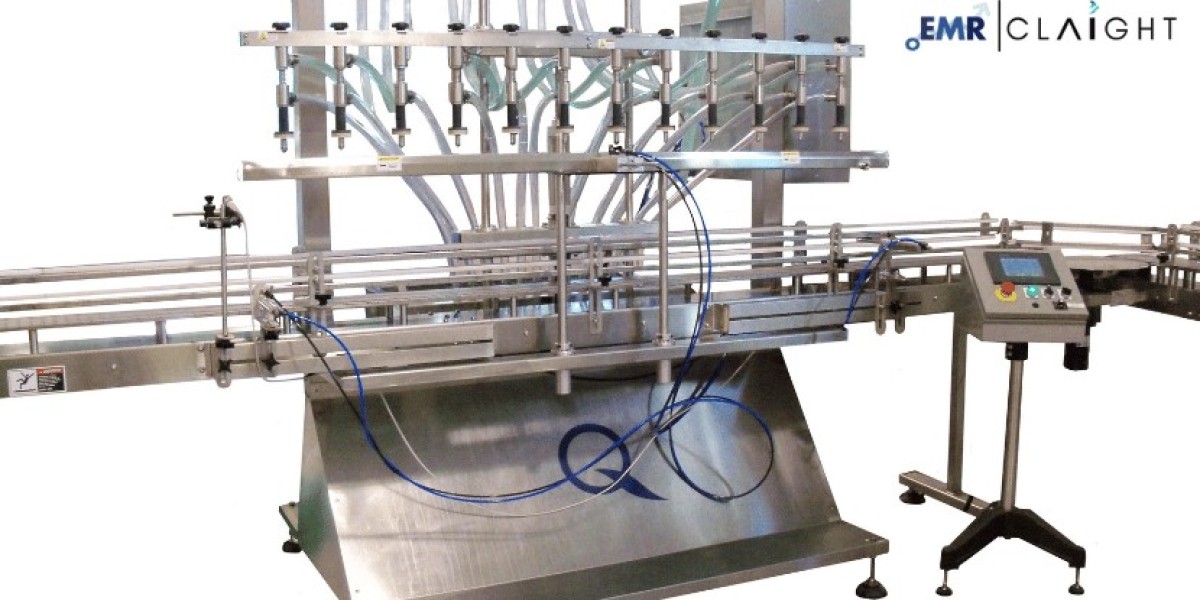

With technological advancements, modern filling machines are now equipped with features like digital control systems, high-speed operations, and flexible configurations to cater to different product types and packaging materials. These machines are designed to handle various filling methods, such as volumetric filling, gravimetric filling, and liquid filling, making them highly versatile and suitable for a wide range of applications.

In the competitive landscape, leading companies in the filling machines market are continually innovating to stay ahead. Strategies such as mergers and acquisitions, product development, and expansion into new geographical markets are being employed by key players to strengthen their market position. Additionally, increasing investment in research and development to improve machine performance and explore new technologies is contributing to market growth.

Filling Machines Market Segmentation

Filling machines are utilized across multiple industries for filling containers with liquid, powder, paste, or granulated products. The market is segmented based on machine type, mode of operation, application, and region.

By Machine Type:

- Liquid Filling Machines

- Paste Filling Machines

- Powder Filling Machines

- Granule Filling Machines

By Mode of Operation:

- Automatic

- Semi-Automatic

- Manual

By Application:

- Food and Beverages

- Pharmaceuticals

- Chemicals

- Cosmetics

- Others

By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Growth Drivers in the Filling Machines Market

The filling machines market is experiencing significant growth due to several key factors. The increasing demand for efficient and automated packaging solutions is a primary driver of market expansion. Automation plays a crucial role in minimizing human intervention in packaging processes, thereby reducing errors and enhancing overall productivity.

Growing Demand for Automation: The shift towards automation in various industries is one of the key drivers of growth in the filling machines market. As businesses aim to enhance operational efficiency and reduce labor costs, automated filling machines have become a preferred choice. Automation not only increases the speed of packaging but also ensures consistent and precise filling, reducing product waste and improving quality control.

Rising Focus on Product Safety and Hygiene: The food and beverage, pharmaceutical, and cosmetic industries are particularly focused on maintaining high levels of product safety and hygiene. Filling machines are designed to meet stringent regulatory standards, ensuring that products are filled in a controlled and contaminant-free environment. This focus on safety and compliance is a significant growth factor, especially in sectors where health and safety are critical.

Technological Advancements: Advancements in technology have led to the development of innovative filling machines with enhanced features such as touch screen interfaces, real-time monitoring, and data analytics. These technologies help manufacturers optimize their filling processes, reduce downtime, and improve overall production efficiency. Additionally, the integration of Industry 4.0 technologies, such as IoT and AI, is enabling smart manufacturing and predictive maintenance in filling machine operations.

Expansion of End-Use Industries: The filling machines market is also benefiting from the expansion of end-use industries such as food and beverages, pharmaceuticals, and personal care products. As these industries grow, the demand for advanced packaging solutions, including filling machines, continues to rise. In particular, the food and beverage industry has seen an increasing need for filling machines due to the growing consumption of packaged foods and beverages worldwide.

Sustainability and Eco-Friendly Packaging: The global push for sustainable and eco-friendly packaging solutions is also influencing the filling machines market. Manufacturers are increasingly developing filling machines that are compatible with eco-friendly packaging materials, such as biodegradable or recyclable containers. This trend aligns with the growing consumer demand for environmentally responsible products and packaging.

Trends and Opportunities in the Filling Machines Market

Several key trends and opportunities are shaping the filling machines market, offering growth potential for manufacturers and suppliers.

Customization and Flexibility: Manufacturers are increasingly seeking filling machines that offer customization and flexibility to accommodate a variety of products and packaging sizes. The ability to switch between different packaging formats and product types without significant downtime is becoming a critical factor for businesses. As a result, manufacturers of filling machines are focusing on developing equipment that can handle multiple configurations and product variants with ease.

Increased Demand for Liquid Filling Machines: The demand for liquid filling machines is on the rise, particularly in industries such as food and beverage, pharmaceuticals, and cosmetics. These machines are widely used for filling liquids of varying viscosities, from water-like substances to thick syrups and creams. The growing consumption of beverages, dairy products, sauces, and cosmetic creams is driving the demand for liquid filling machines, which are equipped with advanced technologies to ensure accuracy and efficiency.

Growth of E-Commerce and Packaging Requirements: The rise of e-commerce has led to increased demand for packaging solutions that ensure safe and efficient delivery of products to consumers. Filling machines play a crucial role in packaging products for e-commerce, especially in sectors like cosmetics and personal care. As online retail continues to expand, the demand for flexible and automated filling machines is expected to grow.

Pharmaceutical Sector Expansion: The pharmaceutical industry is a significant contributor to the growth of the filling machines market. As the demand for medicines, vaccines, and other pharmaceutical products increases, the need for efficient and sterile packaging solutions is rising. Filling machines designed for the pharmaceutical sector are required to meet strict regulatory standards, and advancements in these machines are helping manufacturers meet these requirements.

Sustainability and Energy Efficiency: Sustainability has become a major focus for manufacturers in the filling machines market. There is a growing trend towards the development of energy-efficient filling machines that reduce energy consumption and minimize environmental impact. This focus on sustainability is driven by both regulatory pressures and consumer demand for eco-friendly products.

Competitive Landscape

The filling machines market is characterized by intense competition among key players. Leading companies are focusing on expanding their product portfolios, enhancing technological capabilities, and entering new geographic markets to maintain their competitive edge. Some of the key players in the market include:

Krones AG A global leader in the packaging and filling machinery industry, Krones AG offers a wide range of filling machines for various industries, including beverages, food, and pharmaceuticals. The company is known for its innovative solutions and focus on sustainability.

Tetra Pak International SA Tetra Pak is a major player in the filling machines market, particularly in the food and beverage sector. The company's advanced filling solutions are designed to ensure product safety and quality, and it has a strong presence in emerging markets.

GEA Group AG GEA Group AG is a leading supplier of filling machines for the food, dairy, and pharmaceutical industries. The company's focus on innovation and technology has helped it maintain a strong position in the global market.

Robert Bosch Packaging Technology GmbH Bosch Packaging Technology offers a comprehensive range of filling machines for the pharmaceutical and food industries. The company's focus on precision and efficiency has made it a key player in the market.

ProMach, Inc. ProMach, Inc. is a prominent player in the packaging machinery industry, offering a wide range of filling machines for various applications. The company focuses on providing customized solutions to meet the specific needs of its customers.

Media Contact:

Company Name: Claight Corporation

Contact Person: Eren smith, Corporate Sales Specialist – USA

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com

Aus. Site: https://www.expertmarketresearch.com.au