In the competitive landscape of modern manufacturing, maximizing output while maintaining quality is a critical objective for businesses across various industries. Wire cage welding solutions are essential for producing robust structures used in construction, agriculture, and automotive applications. AMITY CARE has established itself as a leader in this field by providing state-of-the-art wire cage welding machines designed to enhance productivity and efficiency. This article explores how AMITY CARE’s innovative solutions can help manufacturers maximize their output.

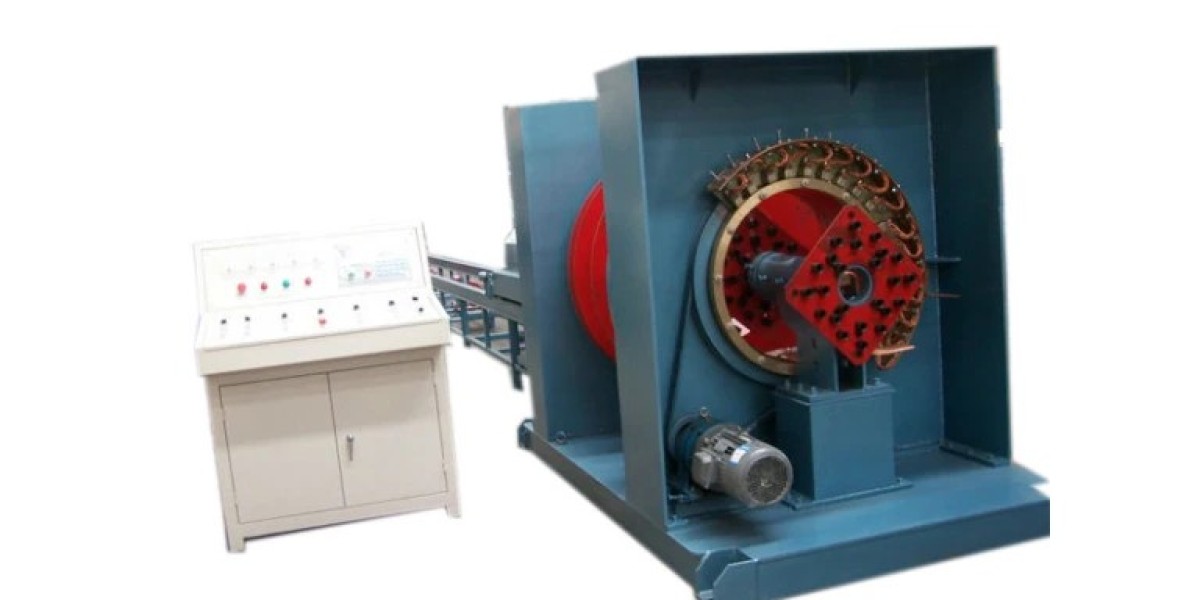

Advanced Automation Technology

One of the key features of AMITY CARE's cage welding machine solutions is advanced automation technology. These machines are equipped with programmable logic controllers (PLCs) that allow operators to set specific parameters for different projects easily. Automation minimizes manual intervention, which not only speeds up the production process but also reduces the likelihood of human error. By automating repetitive tasks, manufacturers can significantly increase their output without compromising on quality.

High-Speed Production Capabilities

AMITY CARE’s wire cage welding machines are engineered for high-speed operation, enabling manufacturers to produce large quantities of welded cages in a shorter time frame compared to traditional methods. The ability to perform rapid welds means that businesses can meet tight deadlines and respond quickly to market demands. This high-speed capability is particularly beneficial in industries where time-to-market is crucial for maintaining a competitive edge.

Precision Engineering for Consistent Quality

Maximizing output does not come at the expense of quality when using AMITY CARE's solutions. The company employs precision engineering techniques that ensure consistent weld quality across all products. With real-time monitoring systems integrated into the machines, operators can track critical parameters such as temperature and pressure during the welding process. This level of precision minimizes defects and ensures that every welded cage meets stringent industry standards, ultimately enhancing customer satisfaction.

Versatility Across Applications

Another advantage of AMITY CARE's wire cage welding solutions is their versatility in handling various wire diameters and materials without extensive adjustments between projects. Whether it involves creating reinforcement cages for concrete or fabricating safety barriers for agricultural use, these machines can adapt seamlessly to different applications. This flexibility allows manufacturers to diversify their product offerings while optimizing existing equipment utilization—maximizing overall output potential.

User-Friendly Interface

AMITY CARE prioritizes user experience by incorporating intuitive interfaces into its wire cage welding machines. Operators find it easy to navigate controls thanks simplified layouts accompanied by comprehensive training resources provided during installation phases . This focus on usability minimizes learning curves associated new technologies enabling teams quickly adapt operations maximizing productivity from day one .

Energy Efficiency Features

In an era where sustainability is increasingly prioritized ,energy consumption associated with manufacturing processes cannot be overlooked either .AMIT YCARE ensures its equipment operates efficiently consuming minimal power while delivering optimal performance levels thus reducing operational costs linked electricity usage over time contributing positively towards bottom line results .

Comprehensive Customer Support

Beyond providing cutting-edge technology ,AMIT YCARE prides itself on offering exceptional customer support services aimed at fostering long-term partnerships with clients . Their dedicated team assists customers from initial consultation stages through installation processes ,providing training sessions tailored specifically according individual needs . Ongoing maintenance programs ensure optimal functioning throughout each machine’s lifespan ,demonstrating an unwavering commitment towards client satisfaction .

Continuous Innovation

The commitment shown by Amity Care towards continuous improvement through innovation further enhances overall efficiencies realized across all facets business operations . Their ongoing research & development efforts aim introducing even more sophisticated features enhancing capabilities further solidifying leadership position industry-wide ensuring relevance amidst evolving landscapes .

Conclusion: A Smart Investment for Manufacturers

In conclusion ,the benefits derived from utilizing AMIT YCARE's advanced wire-cage-welding machinery—including automation speed precision engineering—make them an attractive option for manufacturers looking improve productivity while maintaining high standards output quality moving forward into future endeavors! As demand continues grow globally there is no doubt that Amity Care will remain integral player shaping landscape modern manufacturing practices today! By investing in these innovative solutions businesses position themselves favorably against competitors ensuring sustained success within ever-changing market dynamics!