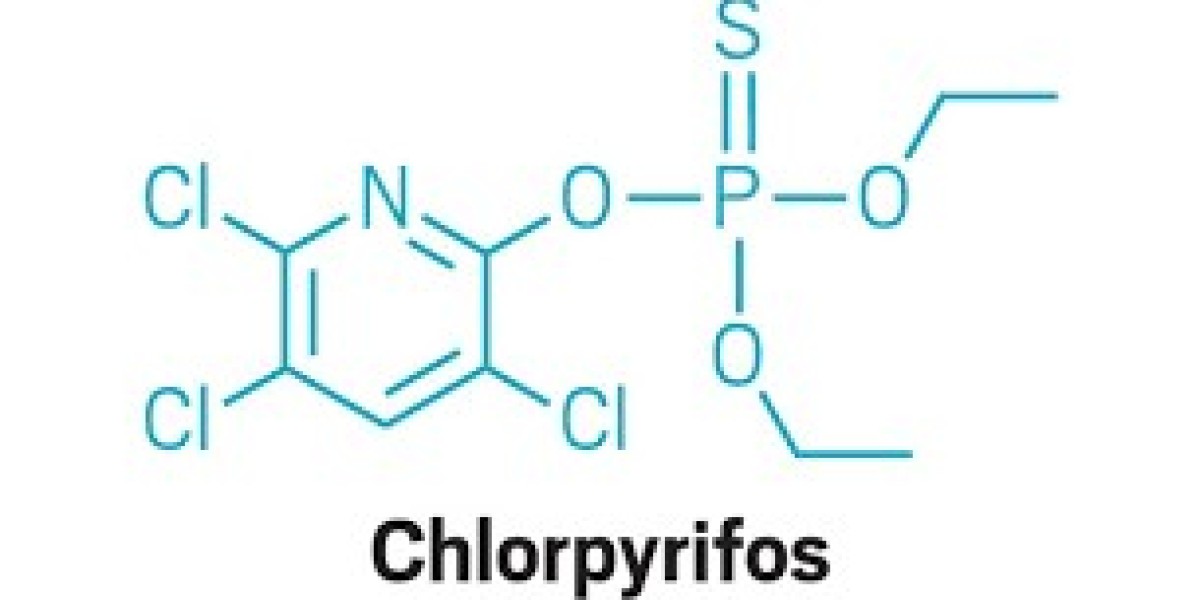

Chlorpyrifos, a widely used organophosphate pesticide, has long been a staple in agricultural practices for controlling pests across a range of crops. Understanding the Chlorpyrifos Production Cost is crucial for stakeholders, including manufacturers, investors, and procurement teams, aiming to optimize their operations and maintain competitiveness in the global market. This comprehensive guide delves into the cost structure, pre-feasibility analysis, industrial trends, labor charges, utilities, logistics, and supply chain dynamics associated with chlorpyrifos production.

Chlorpyrifos: An Overview

Chlorpyrifos is a broad-spectrum insecticide used to control foliage and soil-borne insect pests on a variety of food and feed crops. Despite recent regulatory scrutiny in some regions, it continues to play a vital role in agricultural pest management. The production of chlorpyrifos involves intricate chemical processes and stringent quality control measures to meet regulatory standards, making the analysis of its production costs indispensable.

Request a Free Sample - https://www.procurementresource.com/production-cost-report-store/chlorpyrifos/request-sample

Cost Model for Chlorpyrifos Production

The cost model for chlorpyrifos production comprises several components, each contributing to the overall expenditure. These include:

Raw Materials:

The primary raw materials for chlorpyrifos production include phosphorus trichloride, 3,5,6-trichloro-2-pyridinol (TCP), and solvents.

Market fluctuations in the prices of these raw materials significantly impact production costs.

Manufacturing Costs:

Costs associated with chemical synthesis, reaction monitoring, purification, and packaging processes.

Investments in advanced technologies to enhance efficiency and reduce environmental impact.

Labor Charges:

Skilled labor is essential for operating complex chemical processes.

Regional labor costs and availability influence overall expenses.

Utilities:

Consumption of electricity, water, and other utilities for production processes, including distillation and drying.

Energy efficiency measures can lower utility costs.

Logistics and Supply Chain:

Transportation of raw materials to manufacturing facilities and finished products to end-users.

Efficient supply chain management ensures cost-effectiveness and timely delivery.

Compliance and Environmental Costs:

Adherence to environmental regulations and waste disposal requirements.

Costs related to emissions control and sustainable practices.

Pre-feasibility Analysis for Chlorpyrifos Production

Conducting a pre-feasibility analysis is a vital step in assessing the viability of chlorpyrifos production projects. This involves:

Market Research: Understanding demand trends, competitive landscape, and regulatory environment.

Technical Feasibility: Evaluating the availability of raw materials, technology requirements, and production capacities.

Financial Viability: Analyzing capital investments, operating expenses, and projected revenue streams.

Industrial Trends Shaping Chlorpyrifos Production

Several industrial trends influence the chlorpyrifos production landscape:

Shift Towards Sustainable Practices: Manufacturers are adopting greener technologies to minimize environmental impact.

Regulatory Changes: Evolving regulations in major markets like the US and EU are impacting production and distribution strategies.

R&D Investments: Ongoing research to improve the efficacy and safety profile of chlorpyrifos while exploring alternatives.

Global Supply Chain Dynamics: Geopolitical factors and trade policies affect the availability and cost of raw materials.

Labor Charges and Utility Costs

Labor charges and utility expenses are pivotal in determining the overall production cost of chlorpyrifos. The reliance on skilled workers for chemical synthesis, quality control, and regulatory compliance drives labor costs. Simultaneously, energy-intensive processes like distillation and chemical reactions contribute to utility expenses. Implementing automation and energy-efficient technologies can help mitigate these costs.

Logistics and Supply Chain Management

Efficient logistics and supply chain management are critical for minimizing production costs and ensuring timely product delivery. Key considerations include:

Raw Material Procurement: Partnering with reliable suppliers to secure high-quality raw materials at competitive prices.

Transportation Efficiency: Optimizing transport routes and modes to reduce shipping costs.

Inventory Management: Maintaining optimal stock levels to avoid overproduction or stockouts.

Request a Free Sample Report

Gain deeper insights into the Chlorpyrifos Production Cost with our detailed report. This comprehensive analysis provides a breakdown of cost components, industrial trends, and strategic recommendations to optimize production processes.

Request Your Free Sample Report - https://www.procurementresource.com/production-cost-report-store/chlorpyrifos/request-sample

Role of Procurement Resource

Procurement Resource is a leading platform offering detailed cost analyses and market insights across a range of industries. Our extensive database and expert analysis enable businesses to make informed decisions and streamline their procurement strategies. From raw material sourcing to supply chain optimization, we provide actionable intelligence to enhance operational efficiency.

Understanding the nuances of Chlorpyrifos Production Cost is critical for navigating the complexities of the pesticide manufacturing sector. By leveraging comprehensive cost models, pre-feasibility analyses, and industrial trends, stakeholders can make strategic decisions that drive profitability and sustainability. With the support of platforms like Procurement Resource, businesses can stay ahead in a competitive and evolving market landscape.

Contact Us:

Company Name: Procurement Resource

Contact Person: Endru Smith

Email: [email protected]

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA