When precision meets innovation, the outcome is transformative. LaserChina takes stainless laser welding to the next level, offering cutting-edge technology that guarantees unparalleled accuracy, efficiency, and durability for a wide range of applications. If you’re in the business of stainless steel fabrication, manufacturing, or custom metalwork, LaserChina is your trusted partner to achieve flawless results every time.

Why Choose Stainless Laser Welding?

Stainless laser welding has redefined how industries approach metal joining. Unlike traditional welding methods, laser welding uses a focused beam of light to fuse stainless steel with remarkable precision. This advanced technique ensures:

- Seamless Joints: Laser welding creates smooth, nearly invisible welds that enhance the structural and aesthetic appeal of stainless steel products.

- Minimal Distortion: Thanks to its concentrated heat application, stainless laser welding minimizes thermal distortion, preserving the integrity of your materials.

- Increased Efficiency: Faster processing times and reduced need for post-weld finishing make laser welding a cost-effective solution.

LaserChina: The Ultimate Stainless Laser Welding Experts

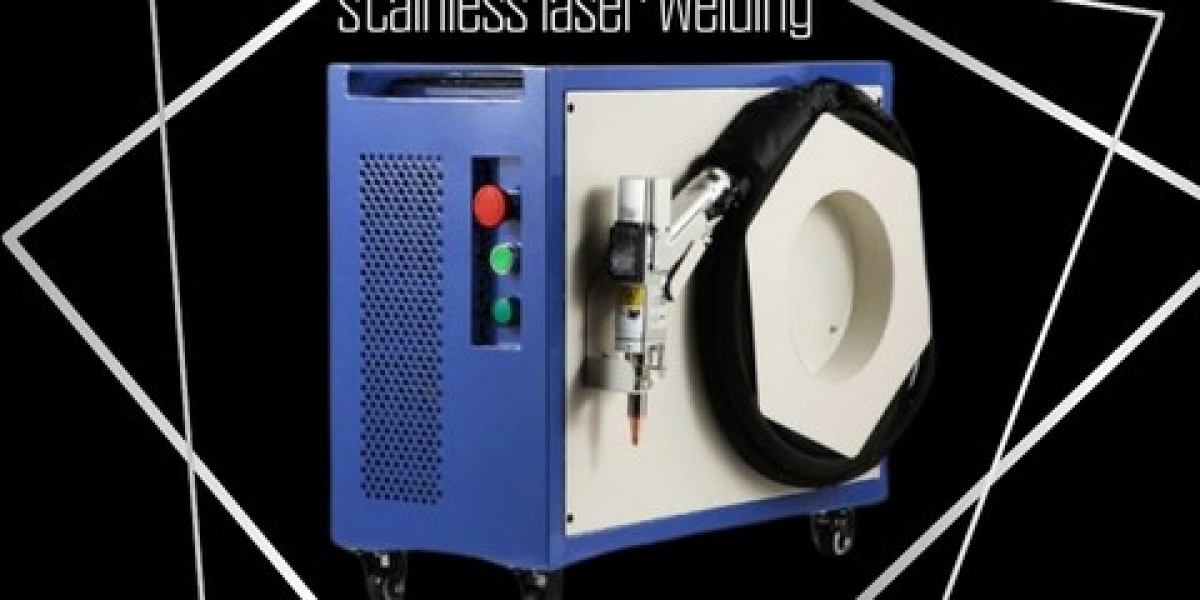

At LaserChina, we understand the challenges and demands of modern metalwork. That’s why we’ve invested in state-of-the-art laser welding equipment and developed innovative solutions tailored to meet the specific needs of our clients. Here’s what sets us apart:

1. Advanced Technology

Our stainless laser welding systems use high-powered lasers for unparalleled precision. Whether you’re working on thin sheets or thicker materials, our machines ensure a clean, precise weld every time.

2. Customizable Solutions

LaserChina offers flexibility for various applications, from automotive and aerospace to medical devices and consumer goods. Our equipment can handle complex geometries and challenging projects effortlessly.

3. Experienced Team

Our team of experts brings years of experience in laser welding. We’re here to guide you through selecting the best solutions for your needs, providing hands-on training, and offering ongoing support to maximize your investment.

4. Eco-Friendly Processes

Stainless laser welding is inherently eco-friendly, producing less waste and requiring fewer consumables than traditional welding methods. LaserChina is committed to sustainability, helping you reduce your carbon footprint without compromising quality.

Applications of Stainless Laser Welding

LaserChina’s solutions are ideal for a diverse range of applications, including:

- Fabrication of Stainless Steel Products: Create sleek and durable components for industries like construction and electronics.

- Medical Equipment Manufacturing: Achieve contamination-free welds for surgical tools and implants.

- Custom Art and Jewelry Design: Produce intricate designs with unmatched precision.

Elevate Your Metalwork with LaserChina

LaserChina is your go-to destination for stainless laser welding solutions that blend innovation, precision, and reliability. Whether you’re upgrading your current processes or exploring laser welding for the first time, we have the tools, expertise, and support to drive your success.

Take the leap toward a smarter, more efficient future in stainless steel welding. Discover how LaserChina can transform your operations by contacting us today. Together, let’s redefine what’s possible in metalworking.

Unlock perfection in stainless steel welding with LaserChina — the future of precision welding is here.