The corrugated box making industry has witnessed remarkable advancements over the years, with technology playing a pivotal role in streamlining the manufacturing process. In today's competitive market landscape, efficiency and precision have become synonymous with success. This evolution can be attributed to the continuous innovation in corrugated box making machines.

Historical Perspective: From Manual to Automated

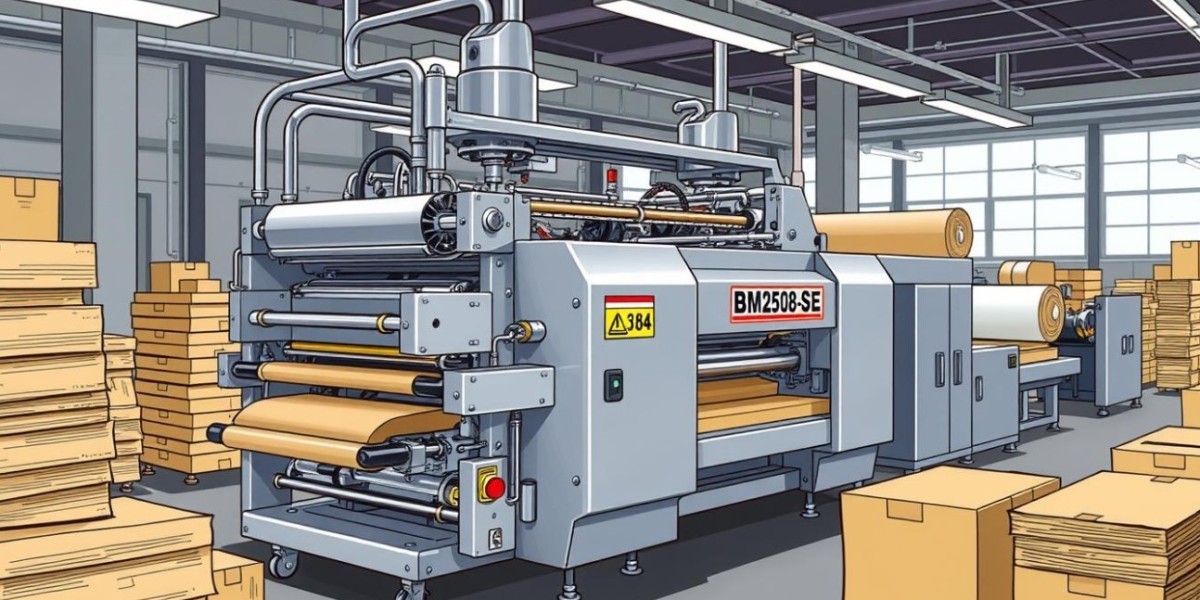

Once reliant on manual labor for production, the introduction of automated corrugated box making machine revolutionized the industry. With the ability to cut, crease, and fold cardboard sheets at a rapid pace while ensuring accuracy, these machines significantly enhanced productivity levels.

Quote from an industry expert:

"The shift towards automation in corrugated box manufacturing not only increased output but also improved product quality by minimizing human errors."

The transition from manual to automated processes allowed companies to meet the growing demand for packaging solutions, paving the way for further advancements in technology.

Cutting-Edge Technology Integration

Over the past decade, technological integration has propelled corrugated box making machines into a new era of efficiency. Computer-controlled systems now govern various aspects of production, including cutting measurements, creasing patterns, and folding sequences. This advanced level of control ensures consistency throughout the manufacturing process.

Moreover, innovations such as automatic feeding systems and real-time monitoring capabilities have further optimized operational workflows. By reducing setup times and enhancing quality control measures, modern corrugated box making machines offer unparalleled precision and reliability.

Sustainability & Environmental Impact

As environmental concerns continue to gain prominence worldwide, sustainability is no longer just a buzzword—it has become a fundamental consideration for manufacturers. Corrugated boxes made from recycled materials have become increasingly popular due to their eco-friendly nature. As such, manufacturers are now facing the challenge of aligning their processes with sustainable practices to reduce their carbon footprint.

Key Questions:

- How can manufacturers adapt their processes to align with sustainable practices?

- What role do corrugated box making machines play in promoting environmental responsibility?

Corrugated box making machines that minimize waste, reduce energy consumption, and utilize recycled materials are vital in promoting sustainability. Additionally, advancements in energy-efficient systems and green manufacturing processes are helping manufacturers reduce their environmental impact.

Industry Trends & Market Dynamics

The global demand for packaging solutions shows no signs of slowing down, which means manufacturers must stay abreast of current trends to remain competitive. Customization options provided by modern corrugated box making machines allow businesses to meet diverse customer requirements efficiently. Whether for branding purposes or specific shipping needs, the ability to create custom boxes is essential.

Key Questions:

- How does customization impact consumer perception and brand loyalty?

- Can flexible production capabilities enhance market responsiveness?

Customization allows businesses to offer unique packaging experiences that foster customer loyalty. Furthermore, flexible production capabilities enable companies to respond quickly to changing market demands, enhancing their ability to compete in a dynamic global market.

Future Outlook: Embracing Innovation

Looking ahead, it is clear that innovation will continue to shape the future of corrugated box making machinery. Emerging technologies such as artificial intelligence (A.I.) and machine learning hold immense potential for optimizing production processes further. By leveraging data analytics for predictive maintenance or incorporating robotics for intricate tasks, manufacturers can increase operational efficiencies and reduce downtime.

In Summary,

the evolution of corrugated box making machines signifies more than just technological progress—it embodies a commitment towards excellence in craftsmanship, sustainability, and customer satisfaction.

Key Question:

- What strategies should companies adopt to capitalize on emerging technologies like A.I., IoT (Internet-of-Things), or robotics within the realm of packaging solutions?

To capitalize on emerging technologies, companies should invest in smart machinery that uses IoT sensors for real-time data collection and AI-driven analytics for predictive maintenance. Robotics can be employed for repetitive and intricate tasks, increasing both precision and speed. Additionally, businesses should foster a culture of continuous learning and innovation to stay at the forefront of technological advancements in packaging solutions.

By embracing these strategies, manufacturers can not only stay competitive but also lead the charge in the future of sustainable, efficient, and high-quality packaging.